ABLG-2

Stationary, immobile ABLG-2 for the cutting of short blocks of various lengths from long blocks

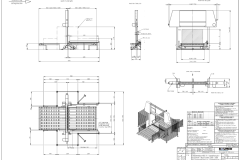

ABLG-2 cutting-off machine with horizontal blade

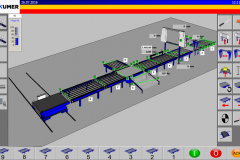

Generally, the ABLG-2 is integrated into the main control of the block storage and/or crane hall

- Very good cutting result as the cutting-off machine with the teflonized binding cuts over the whole block width in one stroke

- By means of length measurement, the block is very precisely fed during belt feed so that even the smallest deviations are prevented (optional).

- Grinding unit for precision-grinding the circulating ground band knife

- In a special version, the cutting-off machines is installed in or upstream of a long splitting machine in order to egalize the block ends or to cut out defective block parts – in this case the control is incoporated in the long splitting machine

Key Facts

Application

Upholstery, mattress, furniture, packaging and automotive industry, producers of technical articlesCutting-off

Material

PUR-ether and polyester, HR, CMHR, visco-elastic foam

Cutting Tool

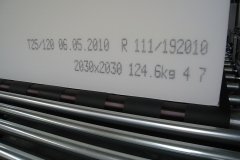

Precision-ground circulating ground knife 30 x 0.45 mm

Technical Data

| Standard | Options | |

| Block Width | 2 200 mm | 2 500 mm |

| Block Height | 1300 mm | 1 600 mm |

Standard

- Frequency-controlled height adjustment motor

- Grinding unit

- B-Con

Options

- Cooling unit

- Grinding dust extraction unit

- Pneumatic adjustment of the grinding unit

- Reinforced version

-

Enforced transport conveyor

Height adjustment

- Frequency-controlled height adjustment of the cutting unit for the individual adaption/allocation of the cutting unit to different foam Qualities. Particularly recommended for very heavy foams or qualities with high strain hardnesses, respectively

Transport conveyors

- For the automation of the block transport, e. g. when the machine is used in cutting lines

- Equipment of the ABLG-2 with transport conveyors of various lengths upstream and downstream of the cutting unit

Various control solutions

- There a various control solutions for numerous ABLG-2 applications available

- From the wiring in a terminal box to an all-automatic control

Automatic grinding unit

- The grinding unit is thrown on pneumatically

- For cyclical grinding during foaming

- Grinding time and cycle intervals are preprogrammed