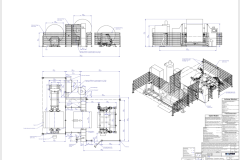

SMW-1

Peeling machine for efficiently peeling round and rectangular blocks with a total weight of up to 1000 kg for producing endless PU film or web material.

SMW-1 peeling machine

A block fixed on a peeling shaft is driven by means of a pressure roller and continuously fed to the knife

- Due to the sturdy design, the machine can accommodate foam blocks with a weight of up to 1 000 kg.

- A driven press cylinder ensures steady, low-tension feeding of material to the knife which prevents deviations in the cutting thickness

- With cutting speeds of up to 150 m/min it is possible to convert high production volumes

- An all-automatic retainer adjustment ensures a constant distance between the leading edge of the knife and the symetry axis of the pressure roller, by this, it is possible to maintain the cutting thickness

- Due to a continuous electronical height adjustment it is possible to peel thicknesses of 1 to 32 mm in steps of 0.01 mm.

- State-of-the-art control technology with control panel enables easy and low-maintenance operation

- The great diameter of the utilised running wheels ensures an ideal bending radius and a long liftetime of the knife

- In connection with an EP profiling machine, the SMW 1 can be combined to an automatic production line

Key Facts

Application

Packaging industry, automotive and vehicle industry, upholstery and mattress industry, insulation and fall protection

Material

PU flexible foam, rebond foam, polystyrene, light rubber rebond

Cutting Tool

Endless band knife with a width of 80 mm and a thickness of 0.6 mm with exchangeable upper and lower binding

Technical Data

| Standard | Options | |

| Block Width | 1 600 mm | 2 200 mm, 2 500 mm, 2 700 mm |

Loading station

- Device for the charging of the peeling machine with a block

- The block with the peeling shaft is perfectly fed to the clamping device.

- A manual lifting of the block into the machine by means of a crane is not necessary anymore.

Trimming station

- For the trimming of the blocks during the peeling process

- For preparing the roll goods to the finished size

Automatic drilling device

- Automatic drilling device for the drilling of core holes for the reception of peeling shafts

- If the peeling shaft is insert, it will be collect automatically

- For creating an exact centrical bore hole

- For round and rectangular blocks

- Minimization of the waste ratio or scrap, respectively

- The loading station for the drilling device serves for the feeding of heavy blocks to the drilling device.

- Eases the workload of the operation staff

- Reduction of the time involved when preparing the roundblocs

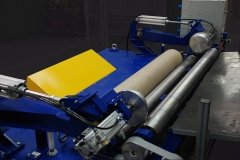

Pressure roller

- Second, additional driven pressure roller

- Drives the blocks the best way possible and feeds the material uniformly to the knife

- Utilised when converting particularly heavy materials, e.g. rebond foam

Reinforced winding unit

- Reinforced and driven winding unit

- Necessary for the converting of heavier materials

- Ensures a uniform winding of the peeled foam