SMW-3

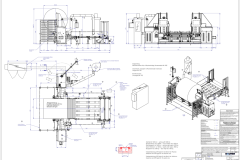

A block fixed on a peeling shaft is driven by means of a tandem press cylinder with longitudinal knurling and continuously fed to the band knife

SMW-3 peeling machine

A block fixed on a peeling shaft is driven by means of a tandem press cylinder with longitudinal knurling and continuously fed to the band knife.

- Due to the sturdy design, the machine can accommodate foam blocks with a weight of up to 3 000 kg

- Standard cutting speed up to 25 m/min (optionally 80 m/min) makes it possible to process high production volumes

- A driven pressure roller serves for a steady feeding of the material to the knife which prevents deviations in the cutting thicknesses

- Due to a infinite electronical height adjustment it is possible to peel thicknesses of 1 to 32 mm in steps of 0.01 mm.

- Peeling shaft reception by means of a clamping chuck for fast and easy reception of the peeling shaft or the inserted foam tube

- An all-automatic retainer adjustment ensures a constant distance between the leading edge of the knife and the symetry axis of the pressure roller, by this, it is possible to maintain the cutting thickness

- A reinforced automatic winding unit with feeding function allows a precise and even winding of the foil

- Reinforced grinding unit for a continuous grinding of the knife

- Latest control technology and the operator panel enable a comfortable and low-maintenance operation

Key Facts

Application

Automotive industry, packaging industry, building industry: flooring and impact sound insulation or anti-slip surfacePeeling

Material

Rubber rebond foam, rebond foam consisting of rubber and cork, PUR foam, cork and similar materials with a volumetric weight of up to 1050 kg/m³

Cutting Tool

Endless band knife 80 mm in width and 1 mm thick in knife bar with interchangeable upper and lower guide binding, as well as variable knife speed

Technical Data

| Standard | Options | |

| Block Width | 1 600 mm | 2 200 mm |

Trimming station

- For the trimming of the blocks during the peeling process

- For preparing the roll goods to the finished size.

Thickness measuring device

- Thickness measuring device for checking the foil thickness

- After the foil has been cut, the thickness is measured at intervals of 11 ms by means of gauge heads

- Ensures a continuous quality check

Circular knife cross cutter

- After reaching the required foil length, the foil can be cut in two by the downstream cross cutting device

Winding unit

- Reinforced and driven winding unit

- Secures a uniform winding of the peeled foam

- Necessary for the converting of heavy material