EP

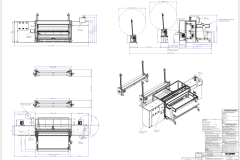

EP profiling machine for the profiling of sheet ware as well as mattress cores made from flexible materials

EP profiling machine

Production of various customized profilings from high densities, strain hardnesses and material thicknesses due to the compact design of the EP

- Winding and unwinding devices allow a continuous production flow for the profiling of sheet ware (option)

- Simple quick change system allows a fast changing of the profile rollers and minimizes thus the production costs

- Customized profile rollers provide a unique selling proportion and increase customer satisfaction and flexibility

- The standard version of the machines provides high, user-friendly and simple ease of use due to latest servo technology, operator panel, automatic knife readjustment in the case of knife wear and infinitely adjustment of the pressure rollers

- Knife retainers in the knife bar serve for additonal guiding and stability of the knife during the cutting process

- As a special version, the EP machine can be delivered as a comination of an EP and ES machine – Apart from profiling, this machine can also be universally used for the splitting of special materials such as PE, EVA, rubber foam, ether foam, etc.

Key Facts

Application

Mattress industry, packaging industry, technical articles for the acoustic industry as well as for the household and consumer goods industryProfiling

Material

PUR soft foam, PUR HR foam, PUR rebond foam, visco-elastic foam, Basotect®

Cutting Tool

Endless band knife with a thickness of 80 x 1 mm, guided in a knife bar with exchangeable upper and lower binding

Technical Data

Standard

- Angle adjustable rear table

- Continuously variable servo drive for profile rollers

- Grinding dust extraction unit

- Grinding unit

- Height adjustable front table

- Knife bar

- B-Con

Options

- Brushing device with roller section behid the lower profile roller

- Carriage for roller change

- Compression belt

- Cooling unit

- Driven transport conveyor behind the knife bar

- Driven transport conveyor on the front table

- Flip-over station for the separation and flipping of the profiled sheets so that the profiled surface is turned upwards

- Profile roller diameter 315 mm, no roller support required

- Reinforced knife drive

- Sets of profiling rollers of different designs

- Support of the upper and lower profiling rollers (Diameter 207 mm)

- Winding and unwinding unit

Winding and unwinding unit

- The unwinding unit upstream of the splitting machine allows the converting of endless roll ware

- The downstream winding unit winds the split material to a diameter of up to 2 000 mm

Frequency-controlled knife drive

- For the profiling of very high densities and in the case of very high compression conditions

Compression belt

- Compression belt, positioned on front of the machine

- By this, a more homogeneous knob structure over the entire profiling surface is achieved

- Facilitates the precise feeding of material to the profiling rollers

- Recommended for the profiliing of shees of a height of at least 150 mm