ROK

Compression and packaging of foam rolls for economic and space-saving storage and transport

ROK roll compression system

ROK Roll compression system for compressing and packaging polyurethane foam in roll form

- Packaging foil is welded automatically when the number of entered wrap layers is finished

- Belt speed of 20 m/min

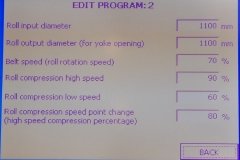

- Up to 5 freely parameterizable compression and packaging programmes enable to an optimum coordination of the processes referred to different foam types

- For roll widths of 2 200 mm or 2 500 mm

- For roll diameters from 400-2 000 mm or 2 500 mm

- Reduction of the foam roll volume of up to 900 mm depending on foam type and machine specification

Key Facts

Application

Roll compression

Material

Soft foams and technical foams

Technical Data

| Standard | Options | |

| Block Width | 2 200 mm | 2 500 mm |

| Block Height | 2000 mm | 2 500 mm |

| Cutting Speed | 1,5 -2,5 min/roll |

Standard

- Automatic welding of the compressed rolls

- Up to 5 freely parameterizable compression and packaging programmes

- PVC belt

Options

- Link conveyor instead of the PVC belt

- Lift for the foil material

- Pillar crane for removing the rolls

- Welding unit for tht packaging rolls

Link conveyor

- The link conveyor enables a more uniform load distribution when compressing the rolls

- The link conveyor is more low-wear and more maintenance-friendly

- Utilization of a link conveyor instead of the PVC belt

Lift

- Lift for the foil material

- For inserting the packaging rolls

Pillar crane

- Monorail crane with special gripping pliers

- Pillar crane for removing the rolls

- For loading and unloading the foam rolls

Welding Unit

- An optional welding unit connects automatically the foil of the two packaging foil rolls

- For the purpose of a continuous packaging process