GF-1200

Milling station combined with an all-automatic cutting-off machine

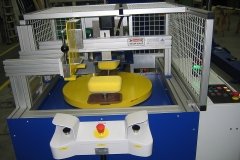

GF-1200 sponge milling machine

Suitable for the bulk production of grip sponge scrubbers made from softfoam with laminations of abrasive or non-woven material.

- Production process: The sponge milling machine is fed with pre-configured foam bars from a magazine – milling of the groove into the foam bars – on the table of the cutting-off station the milled foam bars are bundled to packages of 10 or 20 bars – automatic cutting-off of the packages or cutting-to-size at the vertical cutting-off machine

- Maximum rate of production: 12.000 sponges per hour

- Economic cycle times due to parallel cut-off and stacking function

- Pre-selection of different milling velocities for the production of quality products

- Powerful extraction

- Automatic material feed (optional)

Key Facts

Application

Household sponges, Sponge milling

Material

Soft foam with scouring or non-woven material laminated onto one or both sides

Cutting Tool

Milling head made from aluminium or steel and toothed endless knife in the vertical cutting-off unit

Technical Data

Options

- Automatic charging of the strips made from sheet/roll ware

- Extraction unit for milling dust with motorized vibrating unit with timer

- Extraction unit with a performance of 4 000 m³/h

- Spare milling devices out of nitrided steel in various sizes

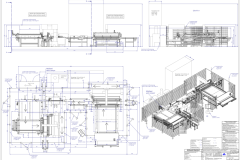

Cutting line for sponge milling

- For the cutting and preparing of foam bars made from sheet or metre goods which are afterwards fed into the GF 1200.

- Can be integrated into the installation

- Increases the automisation level of the installation

- Replacement for the magazine