The unique Maxfoam™ Process allows cells to expand universally, both upwards and downwards, to create an even and consistent foam without wasted raw materials.

A key aspect of the Maxfoam™ Process is the use of gravity in the production of the world’s highest quality foams.

Other foam production techniques create uneven distribution and density, as cells at the bottom and lower levels of the foam are unable to expand in ratio and proportion to cells at the top and higher levels of the foam. The unique Maxfoam Process allows cells to expand universally, both upwards and downwards, to create an even and consistent foam without wasted raw materials.

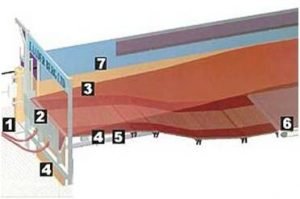

An overview of the Maxfoam™ Process can be seen through the illustration above.

On a Maxfoam™ machine the freshly mixed liquid chemicals are piped from the mixer.

-

These chemcials flow into the bottom fed metal multi-trough.

-

The initial chemical reaction takes place and the foam begins to expand universally.

-

As the foam expands it flows onto the bottom paper.

-

The bottom paper is sliding at a constant speed on the inclined fall-plate.

-

On the fall-plate the foaming trough evenly distributes the foam compound between the side walls to ensure a consistent and evenly produced foam.

The unique Maxfoam™ Process allows adjustment and configuration of the fall-plate to ensure the foam will reach the horizontal conveyor as an even and fully expanded slab. As the principle expansion of the foam takes place downwards over the steeply inclined fall-plate, the surface of the slab is able to follow the near horizontal line of the side paper to create a flat-topped block. All correctly configured Maxfoam™ Machines, combined with the latest chemical technologies, allow you to create square blocks which produce less waste, higher yield and increased savings.

Because of the unique Maxfoam™ Process, adjustment, fall-plate and optimal use of chemicals, Laader Berg® has set the standard for production of flexible polyurethane foams.

Only through Maxfoam™ technology can you produce World Class foam to World Class Standards where foam density and hardness is even and consistent throughout every foam block.