BZM-I

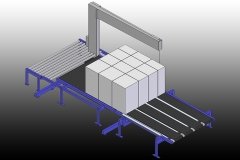

All-automatic vertical cutting machine for the cutting-off of long blocks and for the trimming, cutting or dividing of short blocks

BZM-I block trimming machine

Little space requirement of the machine as the cutting unit is fixed parallel to the conveyor, least space requirement of all comparable machines

- The turning of the knife by 90° by means of pneumatic knife turning devices allows longitudinal and cross cuts in every required position.

- Four different work modes for the trimming of short blocks:1. only at the front and at the rear2. all four sides3. all four sides + centre cuts 4. dividing the block into up to three further single blocks and individual rectangular cuts

- Cutting-off function for long blocks at the BZM-I:-cutting-off a short block of a maximum length of 3050 mm -separating the short block from the long block -cutting/trimming of the short block at all sides, preparation for its subsequent processing

- Exact and fast realisation of various rectangular cuts

- Efficient utilisation of the material with minimum waste

- High efficiency due to a band knife either toothed or ground at both sides which cuts in forward and backward motion

- Two infinitely variable synchronized transport conveyors can seperately move the previously divided blocks and remove them in lengthwise direction

- Employment of the machine as stand-alone version as well as integrated in cutting lines due to the all-automatic mode of operation

- The BZM-I machine is an important connectinn link between rack storage and production process

Key Facts

Application

Upholstery, mattrasses, furniture, packaging and automotive industry as well as technical foamsVertical cutting

Material

Block and sheet ware made from PUR soft foam, PUR rebond foam, visco-elastic foam, latex

Cutting Tool

Ground or toothed band knife with a width of 8-15 mm

Technical Data

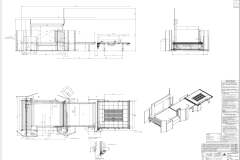

| Standard | Options | |

| Block Width | 2 200 mm | 2 500 mm |

| Block Height | 1 300 mm | 650 mm, 1 000 mm, 1 500 mm, 1 600 mm (only for block length 3 050 mm) |

| Block Length | 2 200 mm | 2 500 mm, 3 050 mm (only for block height 1 600 mm) |

Standard

- B-Con

Options

- Adjustable knife guide

- Cooling unit

- Grinding dust extraction unit

- Knife gap cover

- Loading and unloading conveyors

- Motor-driven grinding unit

- Optical knife grinding control

- Alignment station

- Waste determination

Waste determination

- Measuring device which calculates the percentage of the remaining waste after the block trimming process by means of the PLC control

Alignment station

- Alignment station for the exact positioning of the block

- Useful for the automatic charging of the vertical cutting machine

Conveyors

- Prevention of machine down times

- Equipment with loading and unloading conveyors of various lengths for the converting of short blocks in automatic mode

- Positioning of the belts upstream and downstream of the machine

Knife gap covering

- The knife gap covering prevents the pinching or even the ripping of particularly soft foams or non-woven fabrics in the knife gap

- Realised in the form of a cover for the toothed belt

- Recommended for the converting of particularly soft foams or non-woven materials

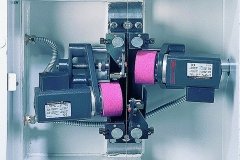

Grinding unit

- Grinding unit for ground knives

- Optional equipment of the machine with ground knives combined with the motor-driven grinding unit

- Optical knife grinding control for a better surveillance of the knife grinding process and for achieving of an optimal cutting appearance

- Possibility of equipping the machine with a grinding dust extraction unit for extracting the grinding dust

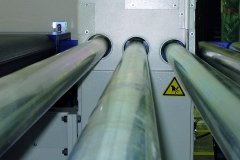

Adjustable knife guide

- The upper knife guide serves as knife protection in the unused cutting area and enhances the knife guiding.

- Reduction of the non-guided knife length for a better fixation of the knife, particularly when cutting smaller blocks or sheets

- Optimizes the cutting quality and enables the utilization of full cutting speed