BSA

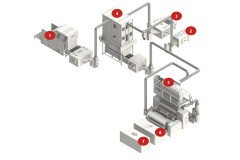

Splitting machine with integrated de-stacking system for the splitting of flexible soft foams

BSA horizontal cutting machine

Unique splitting system: The cutting unit moves horizontally and works with 2 tables which are adjustable in height. On the first table the material is fed, on the second table the split sheet ware is de-stacked.

- Very high productivity due to cutting speeds of up to 100 m/min. Cutting angle and pressure roller are automatically adjusted depending on material and cutting thickness

- Creation of sheet stacks with almost no misalignments by automatically removing and destacking the material

- Due to the utilization of a slim knife bar it is possible to cut a very wide range of different materials with minimal cutting tolerances

- The automatic re-adjustment of the knife secures a constant cutting and tolerance quality

- The machine is suitable for being incorporated into an all-automatic cutting line, e.g. in connection with a vertical contour cutting machine

Key Facts

Application

Upholstery and furniture industry, automotive industry, packaging industry, technical articlesHorizontal cutting

Material

PUR-ether and PUR-ester foams, PUR rebond foam, PE, EVA, reticulated foams, melamine foams, sponge rubber, cellular rubber, Neopren (EPDM),visco

Cutting Tool

Precision-ground endless band knife of 60 mm width, running over 2 wheels, stabilized by a upper and lower binding integrated into the knife bar

Technical Data

| Standard | Options | |

| Block Width | 2 200 mm | |

| Block Height | 1300 mm | 1 500 mm |

| Block Length | 3 050 mm |

Standard

- Stacking System

- Driven pressure roller

- Grinding dust extraction unit

- Grinding unit

- Horizontally movable cutting unit with cutting angle adjustment horizontal 0°-6°

- Knife bar

- B-Con

- Pressure roller adjustable in height by motor

- Retainer adjustment

- Unloading conveyor downstream of the cutting unit

Options

- Cooling unit

- Table I with controlled vacuum units

- Table II with chain conveyor for pallets

Driven pressure roller

- Necessary for the cutting of thin sheets and special materials

Motor-driven angle adjustment

- Optimum cutting angle for different materials and cutting thicknesses

Vacuum unit

- For the cutting of special materials which do not stay upon the table on their own due to their low dead weight

- High cutting accuracy due to the excellent fixation of the sheets and blocks

- Frequency-controlled vacuum unit which regulates the suction power. For special foam qualities as well as for decreasing block height

Pallet conveying system

- Increase of productivity through all-automatic stacking

- The cut material is stacked onto several pallets and unloaded on the pallets afterwards by means of a chain conveyor