BSL-204

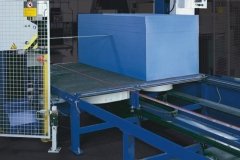

BSL-204 horizontal cutting machine with reversing table and maximum holding power through an on-board vacuum unit

BSL-204 horizontal cutting machine

Perfect suitability for the all-automatic splitting and cutting of different materials with leightweight or medium densities

- Low throughput rates due to a maximum velocity of 80 m/min

- Effective increase in productivity

- Generation of ideal cutting angles and cutting of precise cutting thicknesses thanks to the all-automatic angle adjustment of the cutting unit

- Long knife lifetime and low set-up costs as the knife is relieved of the strain as it does not need to be turned due to the swivelling cutting unit

- Permanently high cutting precion throughout the knife lifetime thanks to the employment of a band knife of 30 mm width which is ground by an integrated grinding unit.

- Very precise cutting tolerances through high tension of the binding

- Minimization of an off-set of the cut sheets

Key Facts

Application

Furniture and mattresses industry, automotive industry, packaging industry, technical articles, filter industryHorizontal cutting

Material

PUR foam and PUR rebond foam, visco foams, Basotect®, latex, reticulated foams

Cutting Tool

The machine is equipped with an endless bandknife of 30 mm width which runs over 4 wheels in the cutting unit

Technical Data

| Standard | Options | |

| Block Width | 2 200 mm | 2 500 mm |

| Block Height | 1300 mm | 1 500 mm |

| Block Length | 2 200 mm | 3 300 mm, 4 400 mm, 5 500 mm, 6 600 mm |

Standard

- Cutting angle adjustment by pivoting the cutting unit from -1 to 6° by motor

- Grinding dust extraction unit

- Grinding unit

- B-Con

- Vacuum unit

Options

- Binding holder

- Cooling unit

- Loading and unloading conveyors

- Reinforced table drive

- Silicone spraying unit

- Superior non-driven press roller

- Working table with perforated conveyor belts

Bindage holder

- Manually movable centre support for stabilizing the binding during the cutting of high densities and densities such as PUR foam and visco foam

Perforated conveyor belts

- Installation of perforated belts on the working table

- Allows all-automatic operation cycles

- Can be integrated into a cutting line either as single machine or together with other machines

- Then the machine can be equipped with additional loading and unloading conveyors

Vakuum unit

- Moveable vacuum system

- Fans inside the table suck the foam block

- More precise cutting results as the block is fixed and even the slightest shifting of the materail is prevented

Silicone spraying unit

- Wets the knife binding at intervals

- Minimization of frictional forces between the binding and the material to be cut

- Reduced sheet offset