BST-140

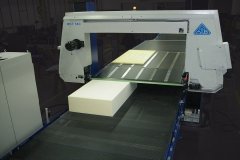

Automatic horizontal cutting machine with reversing belt system for the cutting and splitting of sheets of various thicknesses by a stack cut

BST-140 horizontal cutting machine

The especially reinforced design of the cutting unit ensures a very high binding tension of approx. 10 t and thus provides the best possible way of converting light to higher densities.

- Low throughput rates due to a maximum cutting and return motion speed of 80 m/min

- Effective increase in productivity

- Optimum cutting angle and cutting of precise sheet thicknesses thanks to fully automatic angle adjustment of the cutting unit depending on the cutting thicknesses.

- Permanently high cutting precion throughout the very long knife lifetime thanks to the employment of a band knife of 60 x 0.6 mm.

- Long knife lifetime and low set-up costs as the knife is relieved of the strain as it does not need to be turned thanks to the swivelling cutting unit.

- Grinding duration and grinding cycle can be regulated at the grinding unit by the operator

- A perforated sheet circling around the table serves for the transport of the blocks and allows a fast and uncomplicated integration into fully automated production processes, e.g. cutting lines

Key Facts

Application

Furniture and mattress industry, automotive industry, packaging industry, technical articlesHorizontal cutting

Material

PUR-ether and PUR-ester foam, PU rebond foam, reticulated foams, latex, Basotect® as well as similar materials with light up to higher densities

Cutting Tool

Endless band knife, 60 mm x 0.6 mm, runs over 4 light alloy wheels inside the cutting unit

Technical Data

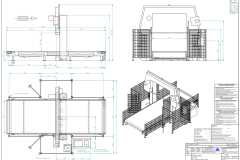

| Standard | Options | |

| Block Width | 2 200 mm | 2 400 mm |

| Block Height | 1300 mm | 1 500 mm |

| Block Length | 3 050 mm | 2 600 mm |

Standard

- Grinding dust extraction unit

- Grinding unit

- B-Con

- Vacuum system

- Motor-driven cutting angle ajustment from 0° to +6°

Options

- Binding holder

- Cooling unit

- Integration into a cutting line

- Loading and unloading conveyor

- Silicone spraying unit

Unloading conveyor

- Height-adjustable unloading conveyor/swivelling area

- The height adjustable unloading conveyor separates the cut sheets (1 – n) from the remaining block and delivers them to the following transport conveyor

- Positioned downstream of the cutting unit of the BST 140

- In order to cut sheet stacks with sheet thicknesses of more than 80 mm, the unloading conveyor can be pneumatically hoisted at its end which thus prevents a misalignment of the split sheets – minimizes the waste rate when cutting the sheet stacks on the

- Utilisation in all-automatic cutting lines in connection with a vertical contour cutting machine

Loading and unloading conveyors

- Optional equipment with loading and unloading conveyors

- Allow an automatic loading and unloading and thus a continuous production flow

- Positioned upstream or downstream of the machine, respectively

- Especially used in cutting lines

- Reduction of machine down times

Vacuum unit in the table

- Vacuum system for a better fixation of the material to be cut in the lower block area

- Fans move together with the table.

- Fans inside the table suck the foam

- Extremely accurate cutting results as the block is fixed and even the slightest shifting of the materail is prevented