BFS

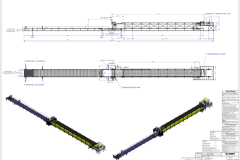

Automatic horizontal cutting machine with reversing belt system and stationary cutting unit for the economic cutting and splitting of sheets into various thicknesses and into lengths of 10 m and upwards. and Automatische Horizontalschneidemaschine mit reversierendem Bandsystemund stationärem Aggregat zum wirtschaftlichen Schneiden und Spalten von Platten in verschiedenste Stärken und in Längen ab 10 m

BFS horizontal cutting machine

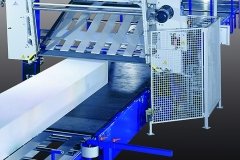

For the splitting of non-glued long blocks

- Simple fabrication of foil ware of minimum thicknesses of 5 mm with an optimum utilisation of the material

- Creation of ideal cutting angles and cutting of accurate sheet thicknesses thanks to the automatic angle adjustment of the cutting unit

- The splitting machine can be equipped with different cutting units in order to convert materials of different qualities, densities and strain hardnesses

- Long knife lifetime and low set-up costs as the knife is relieved of the strain as it does not need to be turned due to the swivelling cutting unit

- For fabricating endless foil ware, the machine can optionally be equipped with a discharging conveyor in order to be able to bond the respective ends of the foils on a special platform.

Key Facts

Application

Automotive industry, mattress and furniture industry, footwear industry, apparel industry, packaging industryHorizontal Cutting

Material

PUR-ether and PUR-ester foam, PUR rebond foam, reticulated foams and similar materials with leight up to high densities

Cutting Tool

Precision-ground circulating ground knife, beginning from 30 x 0.45 mm

Technical Data

| Standard | Options | |

| Block Width | 2 200 mm | 2 500 mm |

| Block Height | 1 300 mm | 1 500 mm |

| Block Length | 10 000 mm | 20 m, 30 m |

Standard

- Grinding dust extraction unit

- Grinding unit

- B-Con

- Vacuum unit

- Variable cutting angle for optimum cutting thickness accuracy

Options

- Discharging transport conveyor

- Extension of transport belts

- Non-driven transport conveyor

- Table extension

- Winding unit

- Working platform

Discharging conveyor

- Transport conveyor for the separation of the foil ware already cut

- Allows the production of endless rolls

- The ends of the foils are manually bonded on a special platform and wound by a winding unit

Working platform

- The operator can bond the foils on the working platform and feed the material to the winding unit

- Facilitates the operation of the machine

Lengthening of the conveyor belt

- The foaming system is designed for a block length of 10 m, and can be extended for block lengths of 20 m/30 m

- The transport conveyors can be extended by steps of 1m (for block width 2 200 mm)

Winding unit

- For coiling the cut and glued foils

- The maximum winding diameter is 1 500 mm