BSV-E

Splitting of glued long blocks (40-60 m)

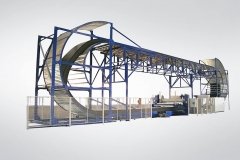

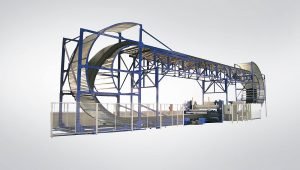

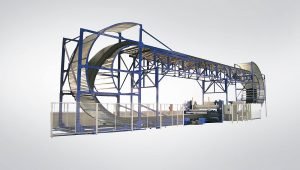

BSV-E long splitting machine

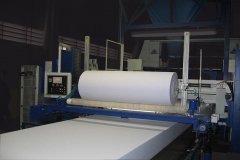

Most economic production of foil ware and best possible utilisation of the material: with foil thicknesses of 1 mm to 50 mm it is possible to wind up a max. roller diameter from 1.5 to 2.4 m, depending on the corresponding machine version

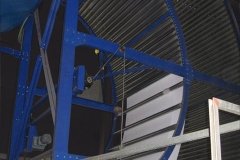

- The long block to be split is continuously fed to the cutting portal by an endless transport system equipped with rollers which is located in two reinforced semi-circular towers.

- Lowering of the cutting unit by the required foil thickness after each block circulation

- For the reason of length compensation, the tower after the cutting unit can be moved by motor

- A motor-driven side guide installed upstream of the cutting unit serves for an accurate block guiding and for bonding the block.

- Maximum cutting velocity of 120 m/min with all versions and for all block lengths

- Maximum total block weight of 5 t with the 60 m version

- Motor-driven feeding bridge for an easy charging of the long blocks

- Precise cutting of various cutting thicknesses through a manual adjustment of pressure rollers and cutting angles by means of a hand wheel (Option: motor-driven).

- Simple operation by means of a modern touch screen which allows a the entry of cutting thickness, cutting length and/or number of rolls

- Continuous, high-quality grinding of the knife by a high-precision grinding unit with pneumatic advance of the cup wheels

Key Facts

Application

Automotive industry, mattress industry, footwear industry, apparel industry, packaging industrySplitting

Material

Polyether and Polyester soft foams with various densities and densities, rebond foam. Precondition: the flexible PUR soft foam used in the looper must be able to adapt itself to the radii of the deflection station without any difficulties

Cutting Tool

Precision-ground circulating ground knife (width 80 mm, thickness 0.6 mm)

Technical Data

| Standard | Options | |

| Block Width | 2 300 mm | 2 500 mm |

| Block Height | 1 300 mm | 1 500 mm |

| Block Length | 50 m, 60 m | 50 m, 60 m |

Standard

- Cooling unit

- Grinding dust extraction unit

- Grinding unit

- Main transport conveyor without vacuum unit

- Manual adjustment of retainer by means of a hand wheel

- Manual cutting angle adjustment

- Manually adjustable non-driven pressure roller

- B-Con

- Motor-driven feeding bridge

- One side stop adjustable by motor

- Operation right Hand

- 3 conveyor drives

Options

- Angle adjustable grinding discs 6-12°

- Re-inforced grinding dust extraction unit

- Motor-driven pressure roller

- Motor driven pressure roller adjustment

- Quick change device for cup wheels

- Reversing mode for short blocks

- Reversing mode in connection with second feeding bridge

- Special lengths on request

- Operation left Hand

- Main transport conveyor with external vacuum

- Winding unit on a separate auf separater lifting platform

- Winding unit with support spindles

- Troughed conveyor belt

- Circular cross cutter

- Catwalk

- Second side stop in trolley conveyor

- Strip cutter (outer trimming)

- Strip cutter with center cut (retractable)

- Ionization unit

- Antistatic brush

- Non-driven clamp fittings

- Conveyor belt inner circle synchronizes with the suspended conveyor

- Cable numbering

- Frequency-controlled vacuum unit

Pressure roller

- Motor-driven pressure roller

- Necessary for the cutting of thin foils (1-5 mm) made from lightweight foam qualities (1-5 mm)

Cross cutter

- Circular knife cross cutter serves for economically cutting off the foils after they have reached the preset foil length

Reverse mode

- Reverse mode in connection with the second feeding bridge

- For cutting long and short blocks made from materials which cannot be converted by a looper

Vacuum unit

- Main conveyor belt with vacuum unit

- For fixing/stabilizing the bock

- The additional fixation of the block directly in the cutting area of the knife prevents a lifting of the block with decreasing block height. By this, even foam qualities which are particularly difficult to process can be completely converted.

Cutting-off machine

- ABLG II for a straight and angular trimming of the head pieces before the long block is glued

- ABLG II S for a straight and angular trimming of the head pieces before the long block is glued. The cutting angle of the ABLG II S can be adjusted between 45 and 90 degrees. The angular cut of the ABLG II S guarantees a larger adherend particularly with foams which a difficult to convert.

- The set-up of the ABLG II and the ABLG II S is before the BSV-E

IS-BA

- For an accurate lateral trimming of the long block

- Adjustment of the cutting units either by motor or manually by hand wheel

- Can be equipped with either a binding or a knife bar

ROK

- ROK Roll compression system for compressing and packaging polyurethane foam in roll form

- Compression and packaging of foam rolls for economic and space-saving storage and transport

- Reduction of the foam roll volume of up to 900 mm depending on foam type and machine specification

- For roll widths of 2 200 mm or 2 500 mm

- For roll diameters from 400-2 000 mm or 2 500 mm

- Belt speed of 20 m/min

- Up to 5 freely parameterizable compression and packaging programmes enable to an optimum coordination of the processes referred to different foam types

- Packaging foil is welded automatically when the number of entered wrap layers is finished