OFS-221 (HORIZONTAL WIRE)

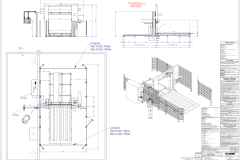

Horizontal contour cutting machine with a stationary cutting unit and reversing table for the cutting of harder material by means of a circulating cutting wire

Horizontal contour cutting machine with circulating special wire OFS-221

A special wire serving as broach can cut precise form parts even out of very hard materials due to its all-round cutting surface

- Cuts every shape required, even right angles and the smallest radii

- Cutting speeds of up to 5 m/min, depending on material and contour

- Continuously pre-selectable cutting speed

- Continuously variable wire speed for the optimal converting of diverse materials and qualities

- An integrated dust extraction unit for the optimal removal of the occurring cutting dust

- Optional equipment of the working table with transport conveyors for an easier loading and unloading

Key Facts

Application

Automotive industry, upholstery and furniture industry, packaging industry, construction engineering, acoustic and heat insulation and insulation technology, Contour cutting (horizontal wire)

Material

PUR rigid foam and soft foam, PUR rebond foam, polystyrene, PE, rock wool/glass wool, Foamglas®, phenol foam, Basotect®

Cutting Tool

Endless, patented special wire with a diamter of 1 – 1.5 mm

Technical Data

-

Standard Options Block Width 2 200 mm 1 600 mm, 2 500 mm Block Height 1 300 mm 1 500 mm Block Length 2 200 mm 2 700 mm, 3 200 mm

Standard

- Charging automatic

- Cooling unit

- Dust extraction unit

- B-Con

- Smooth working table

Options

- Loading/unloading conveyor

- Manual turntable without vacuum unit

- WinCAP

- On-board vaccum in connection with a perforated table sheet

- Wire speed 60 – 90 m/s, can be adjusted in the control panel

- Working table with 4 transport belts

Loading and unloading conveyors

- For the automatic processing of several blocks and various cutting jobs with a list function

- In connection with table belts the machine can be equipped with corresponding transport conveyors for an all-automatic loading and unloading.

- Increase of productivity

Variable wire speed

- Variable wire speed for the individual adaption to foams with different hardnesses and qualities

- Even more accurate and clean cutting

- Prevents the melting of special material with the wire

Reversing table with belts

- Belts on the table for an easy transport of the blocks

- In connection with loading and unloading conveyors, the idle times of the machine are reduced and the productity is increased

Vacuum unit

- For better fixing of cutting materials

- Especially recommended for materials with light gross densities