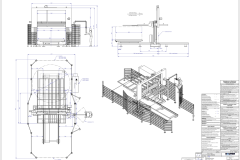

OFS-222 (HORIZONTAL KNIFE)

Equipped with an oscillating knife for most precise cuts

OFS-222 horizontal contour cutting machine

Especially suitable for technical parts which require extreme accuracies and for the converting of material with high densities

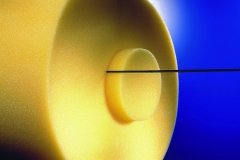

- Clean contour without any marks due to an endlessly turnable knife without any turning points

- Very short machine downtimes thanks to a fast changing of the knife

- Integration of the OFS 222 into automatic cutting lines possible

- Maximum precision when cutting parts for the automotive industry, such as backrests, seats, gaskets, cable insulation or sound insulation components, even at high densities or with Basotect

- Second center support possible for processing technical items

Key Facts

Application

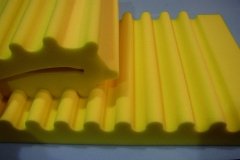

Automotive industry, upholstery and furniture industry, mattrasses and packaging industry, medical technology, technical articlesContour cutting (horizontal knife)

Material

HR and CMHR foam, PUR soft foam, visco foam, Basotect ®, rebond foams, frame foam

Cutting Tool

Precision-ground micro-toothed oscillating knife 3 x 0.6 mm

Technical Data

| Standard | Options | |

| Block Width | 2 300 mm | 2 600 mm |

| Block Height | 1 300 mm | 1 500 mm |

| Block Length | 2 300 mm | 2 600 mm, 2 700 mm, 3 200 mm |

Standard

- All-automatic sheet holding down device

- Centre support movable by motor

- Cooling unit for switch cabinet

- B-Con

- Working table without transport belts

Options

- Charging automatic

- Listing function

- Loading and unloading conveyor for an all-automatic processing

- Working table as all-automatic turntable with transport conveyors

- Working table as manual turntable without transport conveyors

- WinCAP

Loading and unloading conveyors

- Allow an automatic loading and unloading and thus a continuous production flow (list function)

- Recommended for the integration of the machine into an automatic cutting line

- To be positioned upstream and downstream of the machine, available in various lengths

- Prevention of idle times of the machine

Turntable

- Automatic turntable (90°) for the production of three-dimensional parts

- Automatic loading and unloading possible using automatic turntable in conjunction with loading and unloading conveyor

- All-automatic process converting of the blocks in second axial direction without having to move the workpiece by oneself

- The minimiation of manual interference guarantees a constant and high quality of the finished product

- The basic version of this cutting machine is equipped with a manual turntable without belt system

Centre support

- Optional equipment with a movable centre support, either as all-automatic version or driven by motor

- Shortens the free knife length and absorbs the cutting pressure

- Equipped with a knife guide

- Can be moved across the centre of the table by motor

- Particularly recommended for cutting several adjacent blocks at the same time, eg. mattresses or pyramids

- Better cutting quality in connection with higher cutting velocities

Holding down device

- Sheet holding down device for a constant fixing of the block

- Consisting of 5 sheet segments

- Moves synchronously to the axis

- 5 positions of the sheet holding-down device can be reached automatically with the central holder

- Also allows small cuts in connection with the turntable as it rests upon the material over a large area