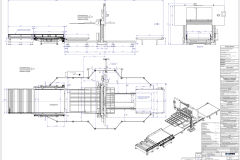

OFS-TWINCUT (HORIZONTAL KNIFE)

Versatile use in the contour cutting techniques due to the alternate use of a circulating or an oscillating knife in a single cutting unit

OFS-Twincut horizontal contour cutting machine

Double functionality of the OFS-Twincut: allows very fast cutting of cushion parts and mattresses by means of the circulating knife (40 m/min max.), guarantees high precise cutting of technical parts by means of the oscillating knife (10 m/min max.)

- Dust-free cuts of any three-dimensional contours with both cutting technologies

- Excellent cutting precision combined with highest cutting speed

- 3 axis machine with CNC control and windows operation system

- The exchanging between a ciculating and an oscillating knife can be done within no time

- Saving of time and money due to an all-automatic cycle with turntable and loading and unloading conveyors.

- WinCAP software for the external generation of material-saving cutting programmes

- Integration in cutting lines

- Possible inclusion of a motor-driven grinder

Key Facts

Application

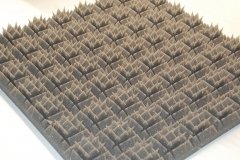

Upholstery, mattress, furniture, packaging and automotive industry, technical articlesContour cutting (horizontal knife)

Material

PUR soft foam PUR HR foam, visco foam, latex, rebond foam, Basotect®

Cutting Tool

Depending on the material, precision-ground micro-toothed or ground knife, either circulating or oscillating

Technical Data

| Standard | Options | |

| Block Width | 2 300 mm | 2 600 mm |

| Block Height | 1 300 mm | 1 500 mm |

| Block Length | 2 300 mm | 2 600 mm, 2 700 mm, 3 200 mm |

Standard

- All-automatic sheet holding down device

- Cooling unit

- Manual turntable

- B-Con

- Semi-automatic centre Support

- Reinforced knife drive

- Adjustable knife speed

Options

- All-automatic centre support

- Automatic turntable with continuous belt

- Grinding unit with grinding dust extraction unit

- Loading and unloading conveyor

- WinCAP

- Working table with belt for loading and unloading

- Separator

Loading and unloading conveyors

- Allow an automatic loading and unloading and thus a continuous production flow

- Positioning upstream or downstream of the machine

- Prevention of idle times of the machine

Turntable

- The automatic turntable can be turned by 90° upstream or downstream of the cutting unit

- Allows the cutting of three-dimensional contours

Centre support

- Optional equipment with a movable centre support either as all-automatic version or driven by motor

- Shortens the free knife length and absorbs the cutting pressure

- Equipped with a knife guide

- Better cutting quality combined with higher cutting velocities

- Can be moved across the centre of the table by motor

- Highly recommended for the cutting of several blocks at the same time, such as mattresses or pyramids

Sheet holding down device

- Sheet holding down device for the constant fixing of the block

- Moves synchronously to the axis

- Consisting of 5 sheet segments

- There are 5 positions of the sheet holding down device which can be automatically approached by the holding down device.

- Also allows small cuts in connection with the turntable as it rests upon the material over a large area

POS connection

- The machines can be incorporated into the POS (Production Order System) superior job management system by means of a corresponding software module and are hence part of a complete machine network.